Your new solar pump is not working right. You have spent time and money, but there is no water. This is a common problem, but it is easy to fix.

The most common installation mistakes include incorrect wiring, improper pump sizing, poor solar panel placement, neglecting dry-run protection, and using the wrong pipe size. These errors can cause system failure or reduced efficiency. Always check your connections and system design before starting the pump.

"Solar Well Pump Installation"

"Solar Well Pump Installation"

I've been in this business for many years. At my factory, HYBSUN, we produce thousands of solar well pumps every month. We get calls from distributors like Daniel in South Africa and buyers in the United States. The problems are often very simple to solve. Let's look at these common mistakes one by one. This will help you avoid them and save you time and money. It will also prevent a lot of frustration.

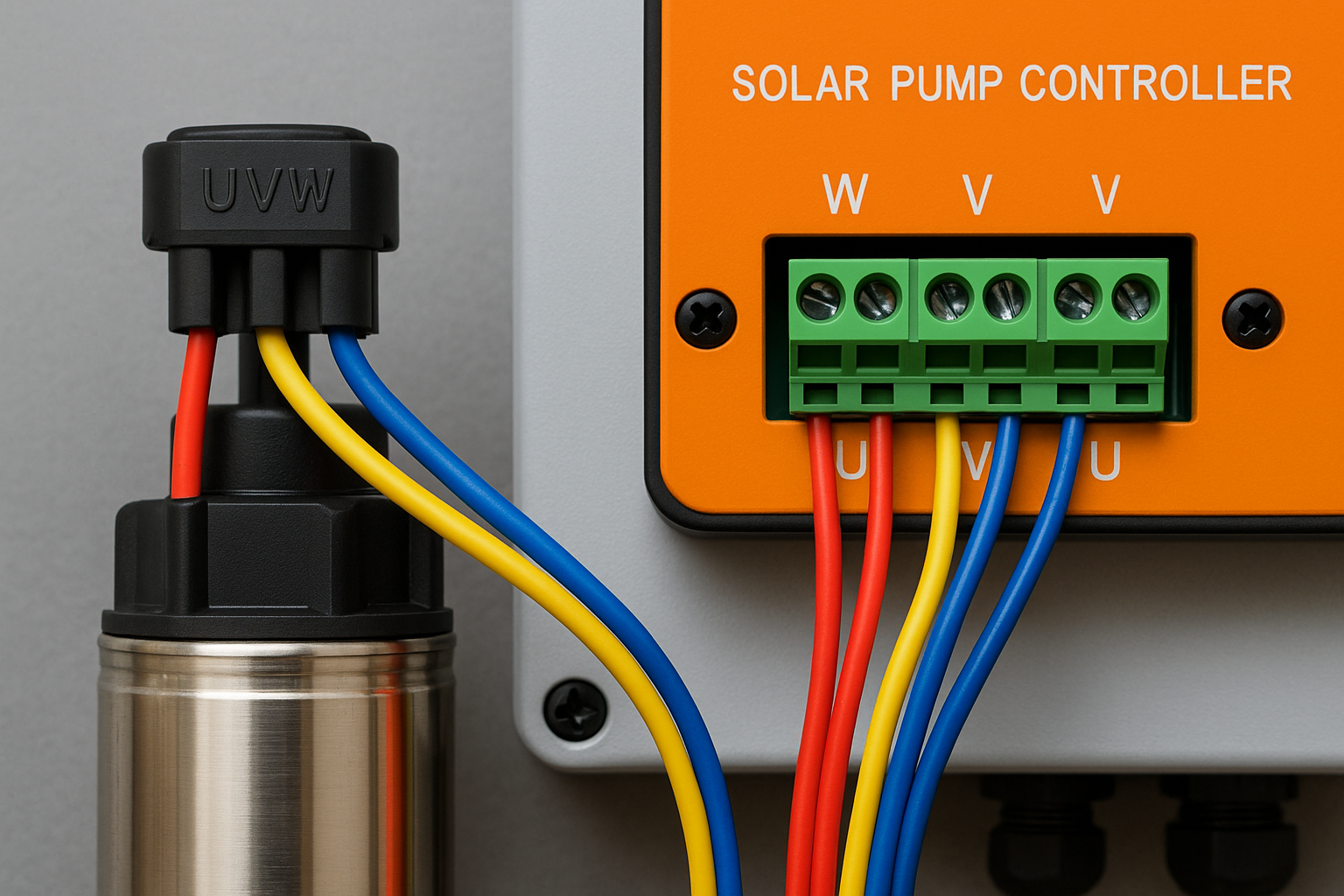

Did you connect the UVW wires correctly?

The wires are all connected. You think it's right, but the pump just hums or runs backward. A simple wiring mix-up can stop your entire project before it starts.

Always match the UVW connector from the pump to the UVW terminals on the controller. Mismatching these three wires is the number one reason for pump failure on startup. Double-check that U goes to U, V to V, and W to W for correct operation.

"UVW Wire Connectors"

"UVW Wire Connectors"

I get calls about this all the time. This is the first thing I ask customers to check. "Did you connect U to U, V to V, and W to W?" I remember a call from a client in Uganda. His new pump was running, but no water was coming out. He was sure the pump was broken. We asked him to check the UVW wires. He had swapped V and W. Once he fixed it, water flowed perfectly. This simple five-minute check saved him from sending the pump back to us.

Why UVW Wires are Special

Our solar pumps use 3-phase motors. These motors need three separate electrical currents to spin in the right direction. The UVW wires deliver these three currents. If you mix them up, the motor will spin backward or not at all. A pump spinning backward will not push water up. It's that simple.

Consequences of Wrong Connections

A wrong connection can cause more than just a lack of water. It can put stress on the motor and bearings over time.

| Connection State | Pump Behavior | Result |

|---|---|---|

| Correct (U-U, V-V, W-W) | Spins correctly | Normal water flow |

| Two Wires Swapped (e.g., U-U, V-W, W-V) | Spins backward | No water, possible humming |

| One Wire Disconnected | Does not spin, hums loudly | No water, risk of motor damage |

Before you do anything else, check these three wires. It is the easiest fix.

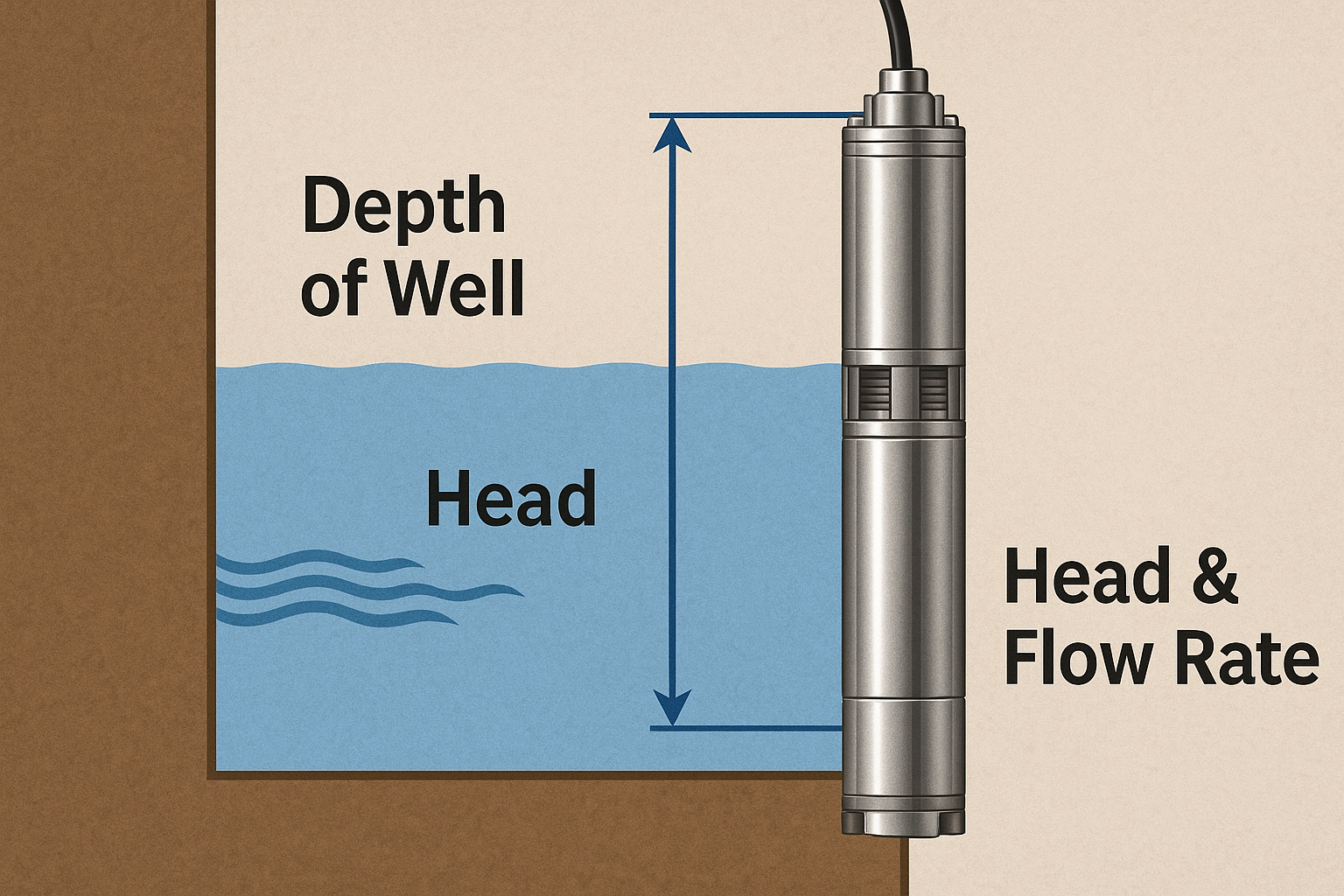

Is your pump the right size for your well?

You bought a powerful pump, but the water flow is weak. Or maybe the pump turns on and off all day. The wrong size pump wastes energy, money, and your time.

Choosing the right pump is not about getting the biggest one. You must match the pump's head and flow rate to your well's depth and your daily water needs. An oversized or undersized pump will be inefficient and wear out much faster.

"Pump Sizing Diagram"

"Pump Sizing Diagram"

A few years ago, a new distributor in Zambia called me. He was supplying pumps to small farms. A farmer bought a pump with a very high flow rate but a low head. The farmer’s well was very deep. The pump was powerful, but it could not push the water high enough to get out of the well. He needed a multi-stage pump with a higher "head" rating. We helped him choose the correct model, and his customer was very happy. This taught him to always ask about the well depth first.

Understanding Head and Flow

You need to know two main things to size a pump.

- Total Dynamic Head (TDH): This is the total height the pump needs to push the water. It includes the depth of your well plus any height it needs to push the water into a tank.

- Flow Rate: This is how much water you need per hour or per day.

Why Bigger Isn't Better

An oversized pump is a big problem. It will pump water very fast and then shut off. Then it will turn on again. This is called "cycling." Cycling wears out the motor and the controller. An undersized pump is also a problem. It will run all day but never give you enough water.

| Scenario | Problem | Consequence |

|---|---|---|

| Pump is too big (Oversized) | It cycles on and off frequently. | Wears out the motor and controller. |

| Pump is too small (Undersized) | It runs constantly but provides little water. | Not enough water for needs, pump overworked. |

| Pump is just right | It runs smoothly during peak sun hours. | Efficient, long lifespan, meets water needs. |

Always calculate your needs before you buy. It is the most important step.

Are your solar panels getting enough sun?

The sun is shining brightly, but your pump is barely working. You checked all the connections, and they are fine. The problem might be where you put your solar panels.

Your solar panels must face the sun directly for most of the day. You must avoid shadows from trees, buildings, or other panels. The wrong angle or location can drastically reduce your pump's performance, especially when you need water the most.

"Optimal Solar Panel Placement"

"Optimal Solar Panel Placement"

We had a customer in Thailand who was very unhappy. His system worked great in the morning but was very weak in the afternoon. He sent me photos of his installation. At first, everything looked perfect. Then I asked for photos of the area around the panels. I saw a new building next to his property. This building was casting a shadow on the panels after 2 PM every day. He moved the solar array to another part of his field, and the problem was solved completely.

Finding the Perfect Spot

The location is everything. The panels need direct, unobstructed sunlight from at least 9 AM to 4 PM.

The Enemy: Shade

Even a small shadow can cause big problems. If one part of a panel is shaded, it can reduce the output of the entire solar array. Think of it like a kink in a water hose. The water flow for the whole hose is restricted. For our clients in South Africa, I always remind them that panels should face north. For clients in the United States, they must face south. The correct angle also matters. It should match your latitude for the best year-round performance.

Best Practices for Panel Placement

- Orientation: Face north in the Southern Hemisphere. Face south in the Northern Hemisphere.

- Angle: Set the tilt angle equal to your location's latitude.

- Shade: Check for shade from trees, buildings, or hills throughout the entire day.

- Cleaning: Keep panels clean from dust and dirt. This is very important in places like many parts of Africa.

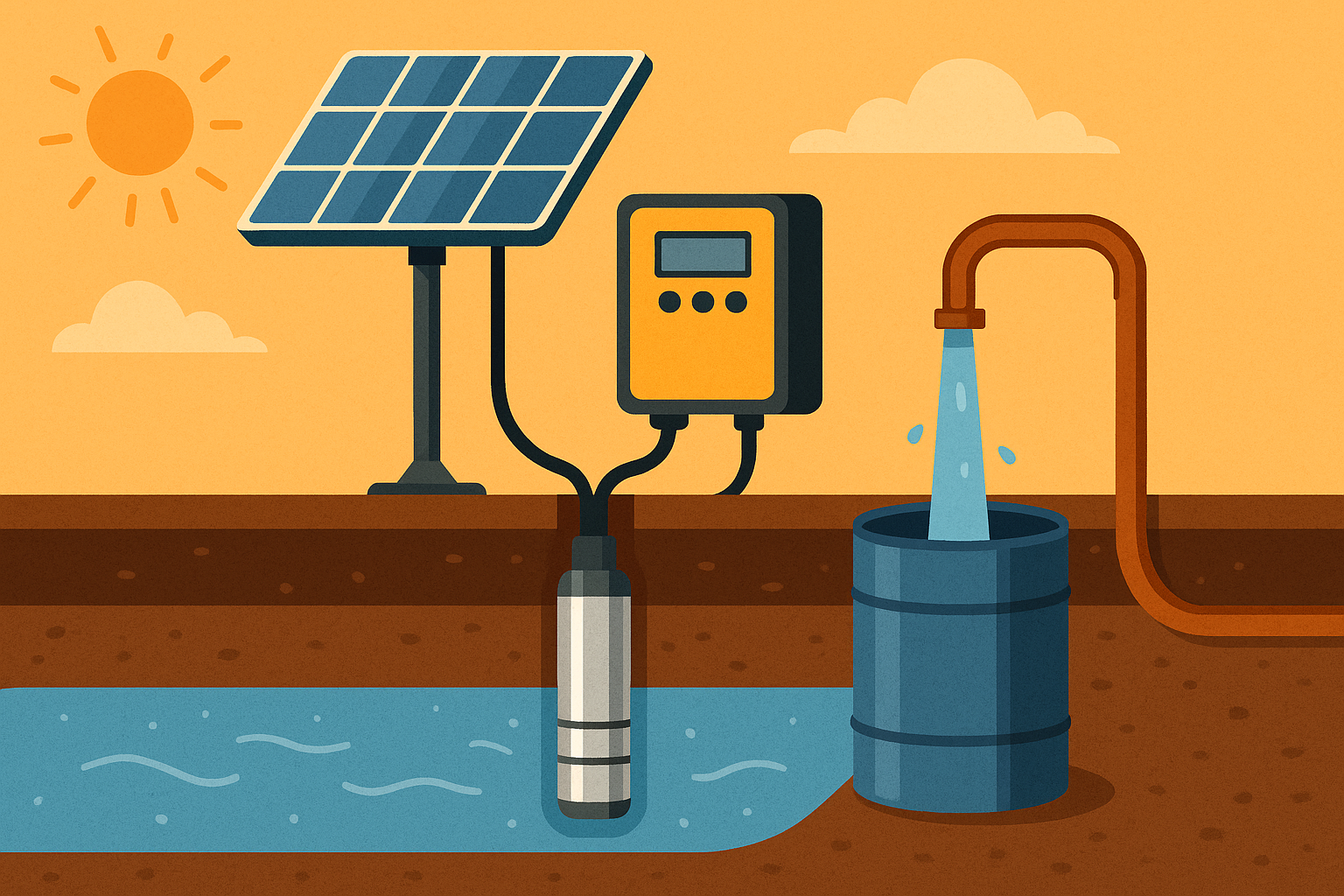

Is your well protected from running dry?

Your well's water level is low. The pump keeps running without water, making a strange, loud noise. Soon, it will burn out, and you will need to buy a new one.

Never run a submersible pump without water. This is called "dry running," and it will destroy the motor very quickly. Our HYBSUN controllers have built-in dry-run protection using sensors or software. Always make sure this feature is enabled and installed correctly.

"Dry Run Protection Sensors"

"Dry Run Protection Sensors"

We build our solar pump inverters with this protection as a standard feature. Water is precious in many of the countries we export to, like Togo and Zambia. Wells can run low. This feature is not optional for us; it is necessary. I always tell our distributors, like Daniel, to show customers how the water level sensors work. You put one sensor just above the pump and another one higher up. When the water level drops below the lower sensor, the controller automatically stops the pump. This protects the farmer's investment.

What is Dry Running?

Submersible pumps use the water around them for cooling and lubrication. When there is no water, the motor quickly overheats. The bearings and seals will fail. This damage is often permanent. A pump can be destroyed in just a few minutes of dry running.

How Our Protection Works

We use a simple and reliable system.

- Well Sensors: Two small probes are lowered into the well with the pump.

- Controller Logic: The controller constantly checks for a connection between the probes. Water completes the circuit.

- Automatic Shutdown: When the water level drops below the bottom probe, the circuit breaks. The controller stops the pump immediately. It will restart only after the water level rises again.

| Protection Method | How it Works | Reliability |

|---|---|---|

| Water Level Sensors | Physical probes detect the presence of water. | Very High |

| Software/Current Sensing | The controller detects a change in motor power draw. | Good, but sensors are better. |

| No Protection | The pump runs until it breaks. | Very Low |

Always install and test the water level sensors. It is cheap insurance for an expensive pump.

Is your pipe size restricting your water flow?

The pump is running strong, and the solar panels are in the full sun. But the water just trickles out of the pipe. The problem might be the pipe you are using.

Using a pipe that is too small increases friction loss. This forces the pump to work harder to push the water, which reduces flow and efficiency. Always check the pump's manual for the recommended outlet pipe diameter and use a pipe of at least that size.

"Pipe Size and Water Flow"

"Pipe Size and Water Flow"

I remember a case with a customer in Uruguay. He was a farm owner and installed one of our larger solar submersible pumps. The pump had a 2-inch outlet. He connected it to a long run of 1-inch pipe that he already had. He called us to complain that the pump was not performing as advertised. He was getting less than half the water he expected. We explained the problem of friction loss. He was skeptical but agreed to try a 2-inch pipe. The next day he called back, amazed. The water flow had more than doubled.

Understanding Friction Loss

Think of it like trying to breathe through a small straw. It's hard. The pump feels the same way when it pushes water through a small pipe. The longer the pipe and the smaller its diameter, the more energy is lost to friction. This lost energy means less water at the end of the pipe.

Choosing the Right Size

The pump's manual will always tell you the minimum recommended pipe size. It's based on the pump's outlet. Never go smaller than this recommendation. In fact, for very long pipe runs (over 100 meters), it is often a good idea to use a pipe that is one size larger than the pump outlet to reduce friction loss even more.

| Pipe Diameter | Flow Potential | Friction Loss | Pump Strain |

|---|---|---|---|

| Too Small | Low | High | High |

| Recommended Size | Good | Moderate | Normal |

| Larger than Recommended | Excellent | Low | Low |

Using the right pipe is a small change that makes a big difference. It ensures you get all the water you paid for.

Conclusion

Installing a solar pump is easy if you avoid these common mistakes. Always check your wiring, size your pump correctly, and protect your investment. Your system will work well.